Victory Solutions

At Victory, we understand the importance of having experienced and skilled professionals to help plan and implement improvement plans.

Our team is comprised of full-time staff members as well as associates with expertise in: -

- Engineering

- Railways

- Food Processing

- Disinfection

- Heating

- Health Products

- Composite Bonding

- Dental

- Plastic Moulding

- Recycling

- Mould Elimination

- Water Purification

With our combined knowledge in these areas, you can rest assured that your project will be handled by knowledgeable individuals who have a deep understanding of the industry.

Select the headings below for more information

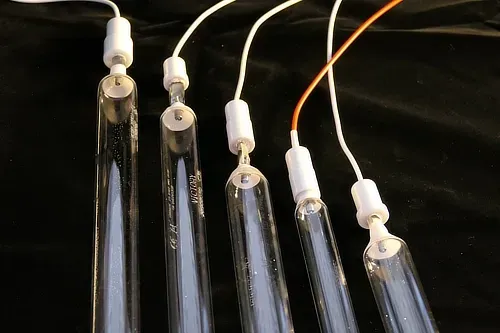

How Does Infrared Work

Manufacturers are looking for heat processes that are easy to control and provide instant heat.

Using infrared systems that use the correct controllers for the application, will meet this requirement.

How does infrared work!

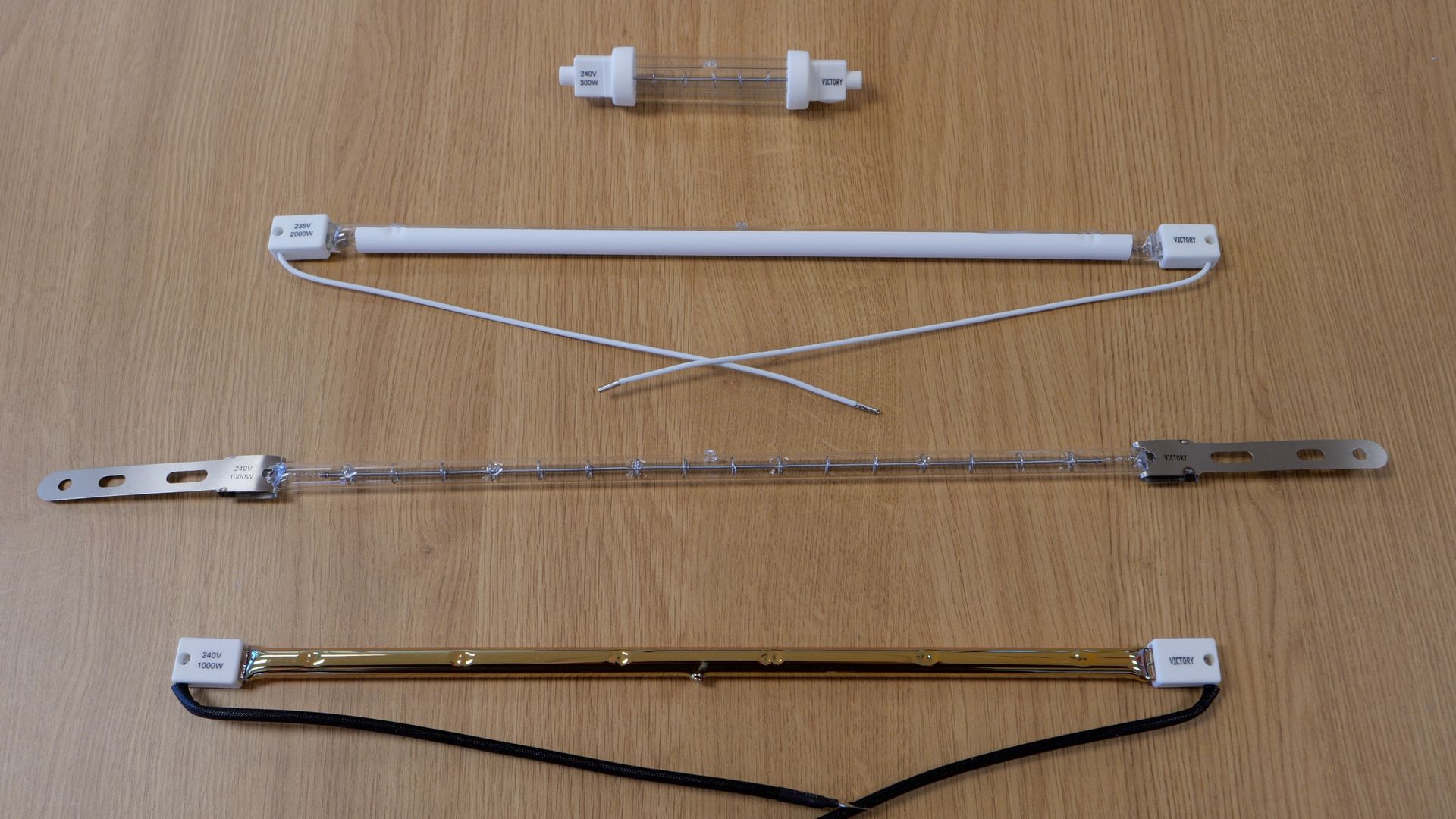

IR lamps transmit infrared electromagnetic waves which create heat when they are absorbed by objects.

In this way, the infrared emitter does not have to be in direct contact with your product and can be placed a suitable distance away while still providing the heat required for your applications.

These infrared waves are not affected by airflow; therefore, a consistent level of heat is maintained regardless of external factors in the location of your machinery.

Each material substrate has its own absorption spectrum, this means that only the infrared at the correct wavelength is absorbed while incorrect wavelengths are either reflected or pass straight through the substrate.

Our Technical Department will work with you to ensure that the emitters we provide have the correct wavelength for the materials in your product to give the optimal heating requirement.

Infrared has the following benefits: - instant heat, more controllable, cheaper to run, are affected less by external factors.